A Transformer Oil Dielectric Tester plays a crucial role in identifying and preventing potential issues with transformer insulation oil by providing insights into the condition of the oil and detecting early signs of degradation.

Here are key ways in which the tester contributes to this process:

- Dielectric Strength Measurement:

- The tester assesses the dielectric strength of the insulation oil. A decrease in dielectric strength may indicate the presence of contaminants or deterioration of the oil, allowing operators to identify potential issues before they escalate.

- Insulation Resistance Measurement:

- By measuring the insulation resistance of the oil, the tester helps identify any reduction in the insulation properties. A decrease in insulation resistance may be indicative of contamination or the breakdown of the oil’s dielectric properties.

- Moisture Content Analysis:

- Transformer Oil Dielectric Testers often include features to measure the moisture content in the oil. Excessive moisture can lead to a reduction in dielectric strength, and early detection allows for preventive actions to remove or mitigate moisture ingress.

- Acid Number Testing:

- Some testers assess the acid number of the oil, providing information about the presence of acidic by-products resulting from oil degradation. Monitoring the acid number helps prevent corrosive damage to transformer components.

- Interfacial Tension Measurement:

- The interfacial tension measurement is a critical parameter for detecting the presence of polar contaminants. A decline in interfacial tension may indicate the presence of contaminants that can affect the oil’s dielectric properties.

- Breakdown Voltage Testing:

- The tester conducts breakdown voltage tests to evaluate the oil’s ability to withstand electrical stress. A decrease in breakdown voltage may indicate the presence of conducting particles or the breakdown of the oil’s insulating properties.

- Particle Count and Size Distribution:

- Advanced testers may include features for measuring particle count and size distribution in the oil. An increase in the number or size of particles can signal mechanical wear or insulation breakdown in the transformer.

- Temperature and Viscosity Monitoring:

- Some testers provide the capability to monitor oil temperature and viscosity. Changes in these parameters can affect the oil’s dielectric performance and may indicate potential issues with the transformer.

- Dissolved Gas Analysis (DGA):

- In some cases, Transformer Oil Dielectric Testers can perform DGA to analyze the gases dissolved in the oil. Elevated levels of specific gases can be indicative of incipient faults, such as overheating or partial discharges.

- Trend Analysis and Historical Data Comparison:

- By regularly performing tests and comparing results over time, the tester allows for trend analysis. Deviations from established baselines can alert operators to emerging issues and facilitate proactive maintenance.

By providing a comprehensive assessment of various parameters, the Transformer Oil Dielectric Tester enables operators to identify potential issues with transformer insulation oil at an early stage. This early detection supports preventive maintenance efforts, helping to extend the lifespan of transformers and prevent costly failures. Regular testing and monitoring become essential components of a proactive maintenance strategy for transformer reliability and performance.

Are there specific advancements or features in modern Transformer Oil Dielectric Testers that have improved the efficiency and accuracy of oil analysis in recent years?

Yes, modern Transformer Oil Dielectric Testers often incorporate advancements and features that have significantly improved the efficiency and accuracy of oil analysis in recent years.

Here are some notable advancements:

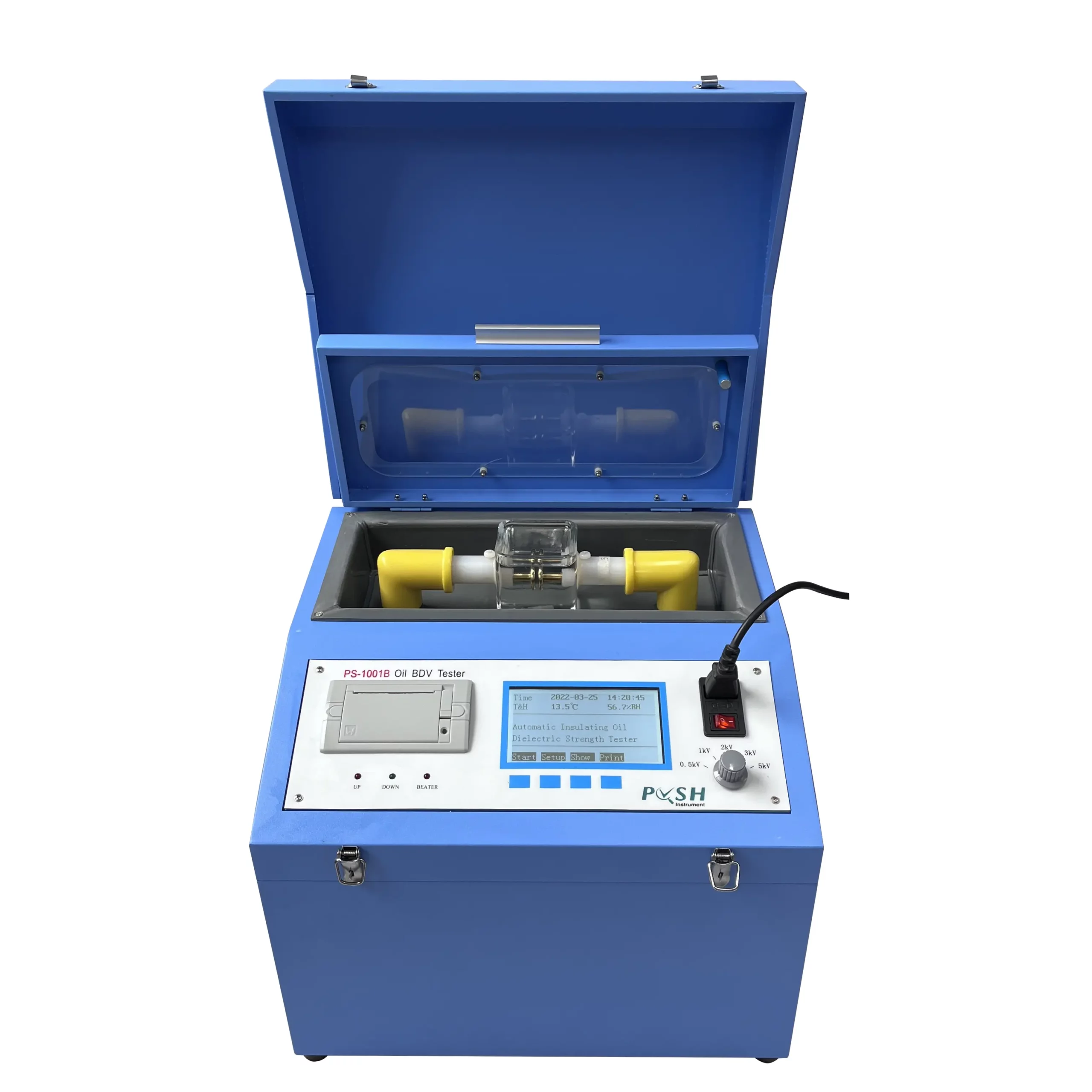

- Automated Testing Processes:

- Many modern testers offer automated testing processes, reducing the need for manual intervention. Automated procedures enhance efficiency, minimize human error, and ensure consistency in testing.

- Multi-Parameter Testing:

- Advanced testers can simultaneously measure multiple parameters, such as dielectric strength, moisture content, acidity, and others. This capability allows for comprehensive oil analysis in a single testing session.

- Integrated Sensors and Probes:

- Some testers feature integrated sensors and probes for real-time monitoring of parameters like temperature, viscosity, and dissolved gases. This continuous monitoring provides a more complete picture of the oil’s condition.

- Portable and Field-Deployable Units:

- The development of portable and field-deployable units allows for on-site testing, reducing downtime and the need for transporting oil samples to a laboratory. This feature is particularly advantageous for large transformers.

- Wireless Connectivity:

- Modern testers often come with wireless connectivity options, enabling data transfer and remote monitoring. transformer oil dielectric tester Operators can access and analyze test results remotely, improving accessibility and efficiency.

- Advanced Data Management Systems:

- Some testers integrate advanced data management systems that store and organize test results. These systems may include features for trend analysis, historical data comparison, and predictive maintenance.

- Cloud-Based Platforms:

- Cloud-based platforms facilitate centralized data storage, analysis, and collaboration. Test results can be securely stored in the cloud, allowing multiple users to access and analyze data from different locations.

- User-Friendly Interfaces:

- Improved user interfaces with touchscreens and intuitive controls enhance the usability of modern testers. User-friendly interfaces simplify the testing process and make it accessible to a broader range of operators.

- Self-Calibration and Diagnostics:

- Some testers include self-calibration features and diagnostic capabilities. Self-calibration ensures the accuracy of measurements, and diagnostic tools can identify potential issues with the tester itself.

- Enhanced Sensitivity and Accuracy:

- Advances in sensor technology have improved the sensitivity and accuracy of measurements. This allows for the detection of smaller changes in oil properties and provides more reliable insights into the oil’s condition.

- Artificial Intelligence (AI) Integration:

- AI algorithms are being integrated into some testers to enhance data analysis. AI can identify patterns, correlations, and anomalies in test results, providing more intelligent and actionable insights.

- Real-time Notifications and Alarms:

- Testers may include real-time notification features that alert operators to critical changes or abnormal conditions. Alarms can prompt immediate action in response to emerging issues.

- Compact Design and Portability:

- Advances in design have led to more compact and portable tester units. This is particularly beneficial for field applications, where space may be limited, and mobility is essential.

These advancements collectively contribute to more efficient, accurate, and streamlined transformer oil analysis processes. As technology continues to evolve, it is likely that Transformer Oil Dielectric Testers will incorporate even more sophisticated features to further enhance their capabilities.