Transformer Breakdown Voltage Testers are designed to accommodate different types and sizes of transformers by providing flexibility in their testing capabilities.

Here are ways in which these testers cater to varying insulation requirements:

- Adjustable Voltage Ranges:

- Transformer Breakdown Voltage Testers often come with adjustable voltage ranges. This feature allows operators to select appropriate voltage levels based on the specific insulation requirements of different transformers. The tester can adapt to both low-voltage and high-voltage transformers.

- Variable Test Durations:

- The tester may offer variable test durations, allowing operators to adjust the duration of the test based on the size and type of the transformer. Larger transformers may require longer test durations to thoroughly assess the insulation.

- Multiple Test Modes:

- Some testers provide multiple test modes to accommodate various transformer sizes and types. These modes can include pre-set testing configurations optimized for specific transformer characteristics.

- Customizable Testing Parameters:

- Users can often customize testing parameters such as the rate of voltage increase and the criteria for determining breakdown voltage. This flexibility ensures that the tester can adapt to the unique insulation requirements of different transformers.

- Compatibility with Different Insulating Materials:

- Transformers may use different types of insulating materials, and the breakdown voltage characteristics can vary. Transformer Breakdown Voltage Testers are designed to work with a variety of insulating materials, including mineral oil, synthetic fluids, and other dielectric materials.

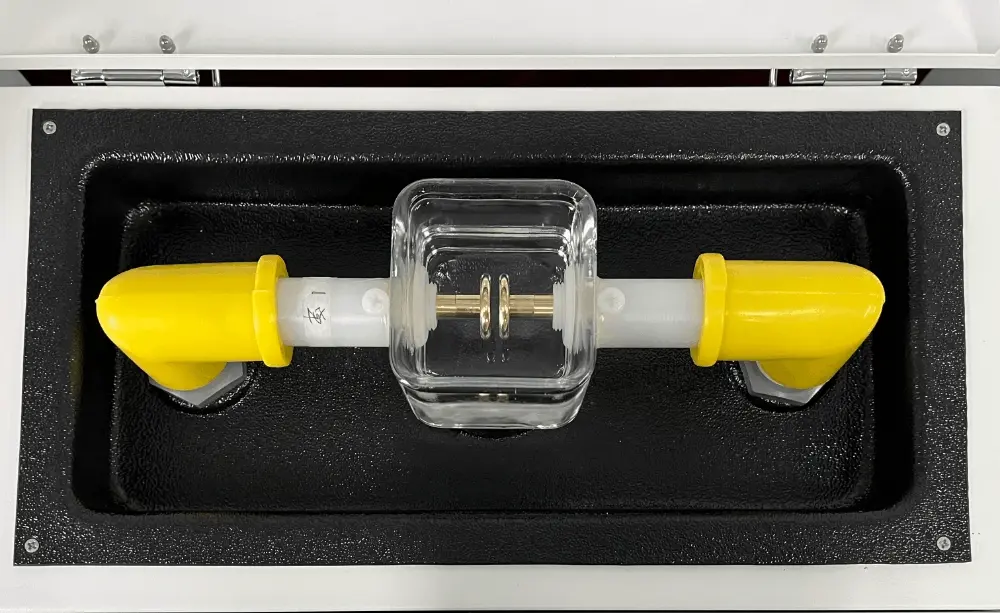

- Various Test Cell Configurations:

- Testers may come with different test cell configurations to accommodate transformers with varying oil volumes. This flexibility allows for testing smaller distribution transformers as well as larger power transformers.

- Portable and On-Site Testing:

- Some testers are designed to be portable, allowing for on-site testing of transformers without the need for transporting the transformer to a testing facility. This is particularly beneficial for larger transformers that may be impractical to move.

- Temperature Compensation:

- The tester may incorporate temperature compensation features to account for variations in temperature that can impact the breakdown voltage. This ensures accurate and reliable testing results, regardless of environmental conditions.

- Safety Features for Various Transformer Types:

- Safety features such as overcurrent protection and interlocking mechanisms are often included to ensure the safety of both the operator and the transformer being tested, regardless of its size or type.

- Compatibility with Industry Standards:

- Transformer Breakdown Voltage Testers are designed to comply with relevant industry standards and regulations. This ensures that the testing process aligns with best practices for transformers of different sizes and types.

By offering these features, Transformer Breakdown Voltage Testers provide adaptability to the diverse insulation requirements of transformers, making them suitable for use across a range of transformer sizes, types, and applications.

What safety precautions should be followed when using the tester to ensure the safety of both the operator and the transformer being tested?

Ensuring the safety of both the operator and the transformer being tested is paramount when using a Transformer Breakdown Voltage Tester.

Here are important safety precautions to follow:

- Qualified Personnel:

- Only trained and qualified personnel should operate the Transformer Breakdown Voltage Tester. Adequate knowledge of testing procedures, safety protocols, and electrical systems is essential.

- Read and Follow Instructions:

- Thoroughly read and understand the manufacturer’s instructions and the user manual before using the tester. Follow recommended procedures and guidelines provided by the equipment manufacturer.

- Personal Protective Equipment (PPE):

- Wear appropriate personal protective equipment, including insulated gloves, safety goggles, and any other PPE recommended by safety standards. PPE is crucial for protecting against potential electrical hazards.

- Inspection of Equipment:

- Before testing, inspect the tester for any signs of damage or wear. Ensure that all cables, connectors, and components are in good condition. Do not use damaged equipment.

- Safe Testing Environment:

- Conduct testing in a designated and well-ventilated area. Ensure that the testing environment is free from hazards and that proper safety measures, such as warning signs and barriers, are in place to prevent unauthorized access.

- Proper Grounding:

- Ensure that the transformer being tested is properly grounded. Follow grounding procedures specified by safety standards to minimize the risk of electric shock.

- Use of Safety Interlocks:

- If the tester is equipped with safety interlocks, Transformer Breakdown Voltage Tester ensure that they are engaged before starting the test. Interlocks help prevent accidental exposure to high voltages.

- Limit Access to Authorized Personnel:

- Restrict access to the testing area to authorized personnel only. Use barriers and warning signs to prevent unintended exposure to high voltages.

- Emergency Procedures:

- Establish clear emergency procedures, including immediate shutdown protocols. Ensure that all operators are familiar with these procedures and know how to respond in case of an emergency.

- Appropriate Voltage Levels:

- Select and apply appropriate voltage levels for testing, considering the specifications of the transformer. Avoid exceeding the recommended voltage levels to prevent damage to the transformer and ensure the safety of the testing process.

- Monitoring Equipment:

- Continuously monitor the condition of the testing equipment during operation. Be vigilant for any abnormal behavior or signs of malfunction and take corrective actions promptly.

- Keep Records:

- Maintain detailed records of the testing process, including the parameters used and the results obtained. Proper documentation is essential for analysis and future reference.

- Training and Certification:

- Ensure that operators are adequately trained and certified for using the Transformer Breakdown Voltage Tester. Regular training sessions can help reinforce safety practices.

- Compliance with Standards:

- Adhere to relevant industry standards and regulations governing transformer testing. Compliance with these standards ensures that the testing process follows established safety practices.

By diligently following these safety precautions, operators can minimize risks and create a safe testing environment for both themselves and the transformers being tested. Safety is integral to the effective and responsible use of Transformer Breakdown Voltage Testers.