22 gauge fine wire staples are a type of staple that are commonly used in upholstery, woodworking, and other applications where a small, discreet staple is required.

Here are some key features and uses of 22 gauge fine wire staples:

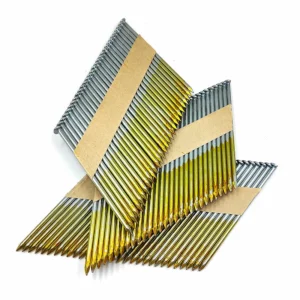

Size and shape: 22 gauge fine wire staples are thin and narrow, with a wire diameter of approximately 0.6mm. They are typically U-shaped or C-shaped, with two sharp points that penetrate the material being stapled.

Material: 22 gauge fine wire staples are made from a variety of materials, including steel, stainless steel, and galvanized steel. The material used will depend on the specific application and the level of corrosion resistance required.

Applications: 22 gauge fine wire staples are commonly used in upholstery and woodworking applications, such as attaching fabric to furniture frames, securing trim and molding, and assembling wooden frames and structures. They can also be used in packaging and labeling applications, as well as in arts and crafts projects.

Staple gun compatibility: 22 gauge fine wire staples are compatible with a variety of staple guns, including manual and pneumatic models. It is important to use the correct size and type of staple for the specific staple gun being used.

Benefits: 22 gauge fine wire staples are a good choice for applications where a discreet and low-profile staple is required. They are less likely to leave visible marks or damage the material being stapled than larger staples. They are also easier to remove if necessary.

Overall, 22 gauge fine wire staples are a versatile and useful type of staple for a variety of applications. They provide a discreet and low-profile fastening option, while still providing a secure hold.

When choosing the right staple for a specific application, there are several factors to consider.

Here are some key factors to keep in mind:

Material being stapled: The type of material being stapled is a critical factor in determining the appropriate staple. 22 gauge fine wire staples Different materials require different types of staples to ensure a secure hold. For example, softer materials such as fabrics or cardboard may require a finer gauge staple, while harder materials such as wood or metal may require a heavier gauge staple.

Staple size and shape: Staples come in a variety of sizes and shapes, including U-shaped, C-shaped, and T-shaped. The size and shape of the staple will depend on the specific application and the thickness of the material being stapled.

Staple penetration: The staple must penetrate the material sufficiently to provide a secure hold, but not so deeply as to damage the material. The length of the staple legs and the angle of the staple gun can affect the depth of penetration.

Staple strength: The strength of the staple is important in determining whether it can hold up to the weight or tension of the material being stapled. Staples made of stronger materials such as stainless steel or galvanized steel may be required for heavy-duty applications.

Staple gun compatibility: Different types of staple guns are designed to work with specific sizes and types of staples. It is important to choose staples that are compatible with the staple gun being used.

Environmental factors: Environmental factors such as humidity, temperature, and exposure to chemicals or UV light can affect the performance of staples. It is important to choose staples that are appropriate for the specific environmental conditions of the application.

Overall, choosing the right staple for a specific application requires careful consideration of the material being stapled, the size and shape of the staple, the strength of the staple, and the compatibility with the staple gun being used. By taking these factors into account, you can ensure a secure and successful staple installation.